What is Digital Textile Printing?

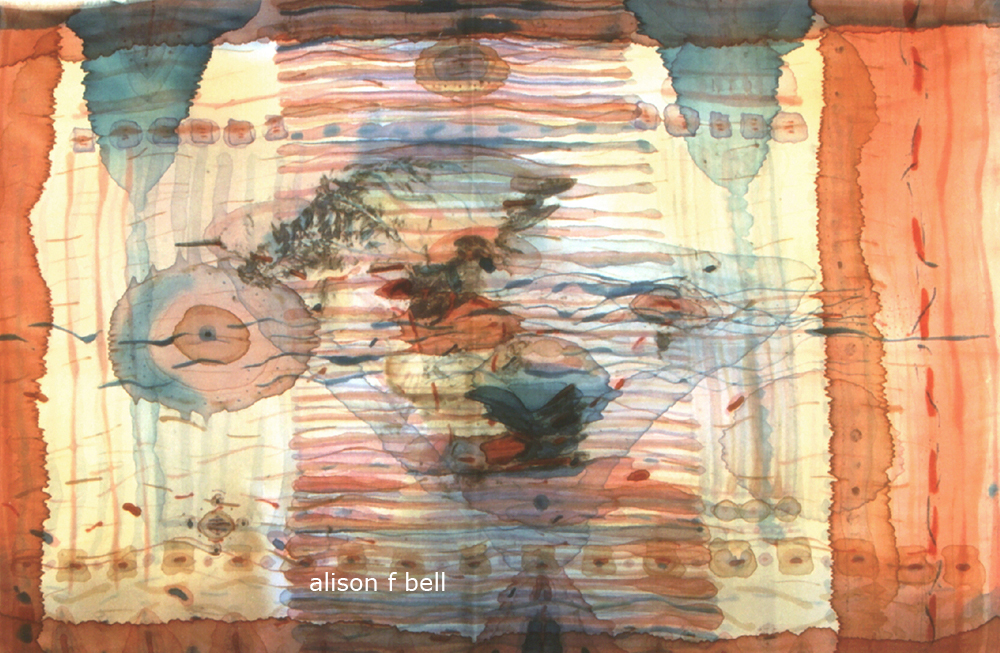

'Digital textile printing is described as any ink jet based method of printing colorants onto fabric. Most notably, digital textile printing is referred to when identifying either printing smaller designs onto garments (t-shirts, dresses, promotional wear; abbreviated as DTG, which stands for Direct to Garment) and printing larger designs onto large format rolls of textile. The latter is a growing trend in visual communication, where advertisement and corporate branding is printed onto polyester media. Examples are: flags, banners, signs, retail graphics.

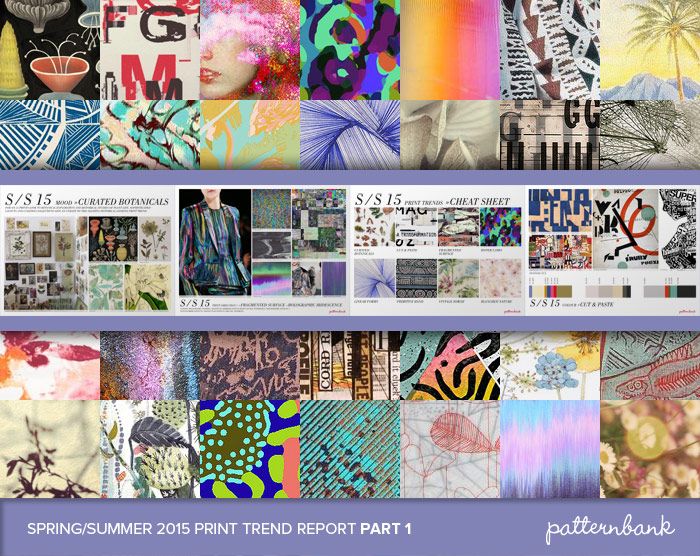

Types of printing can be divided into: Direct Print, Discharge Print, Resist Print, Pigment Print, Specialty Print

Digital textile printing started in the late 1980s as a possible replacement for analog screen printing. With the development of a dye-sublimation printer in the early 1990s, it became possible to print with low energy sublimation inks and high energy disperse direct inks directly onto textile media, as opposed to print dye-sublimation inks on a transfer paper and, in a separate process using a heat press, transfer it to the fabric.

It was patented in 1968 and popularised in the 1990s with the creation of more affordable digital printers, and in the last thirty years has opened up many new options for textile designers and artists. Since its beginning that it was quite expensive is now extremely affordable way to dye and print on textiles and vide range still growing amount of materials. Provides the capability to print detailed designs in fast brilliant colours.

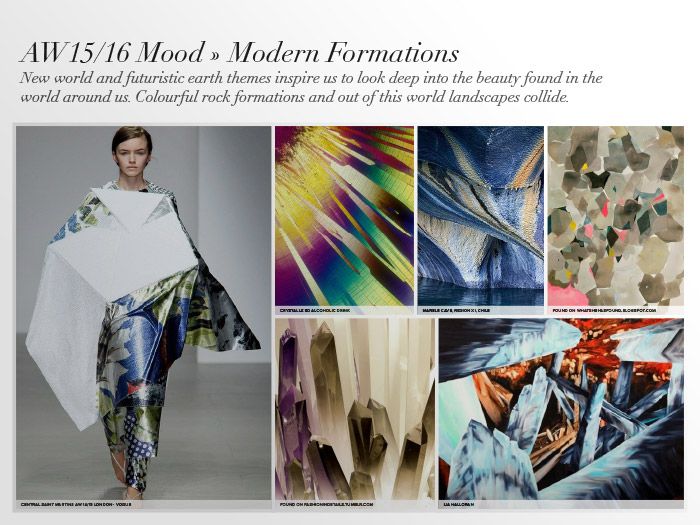

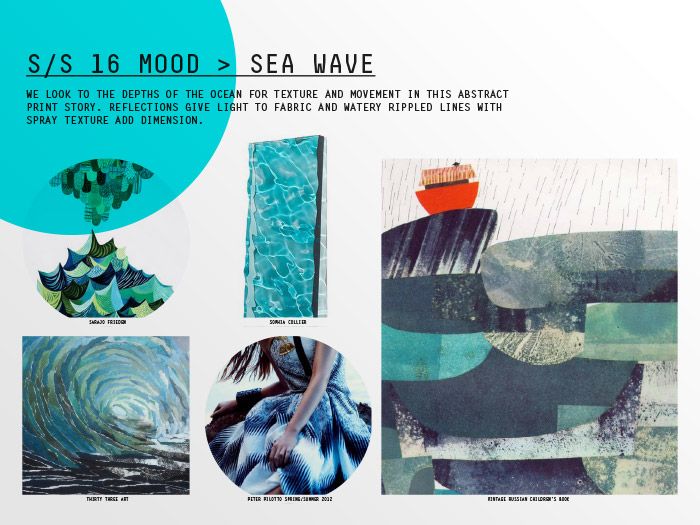

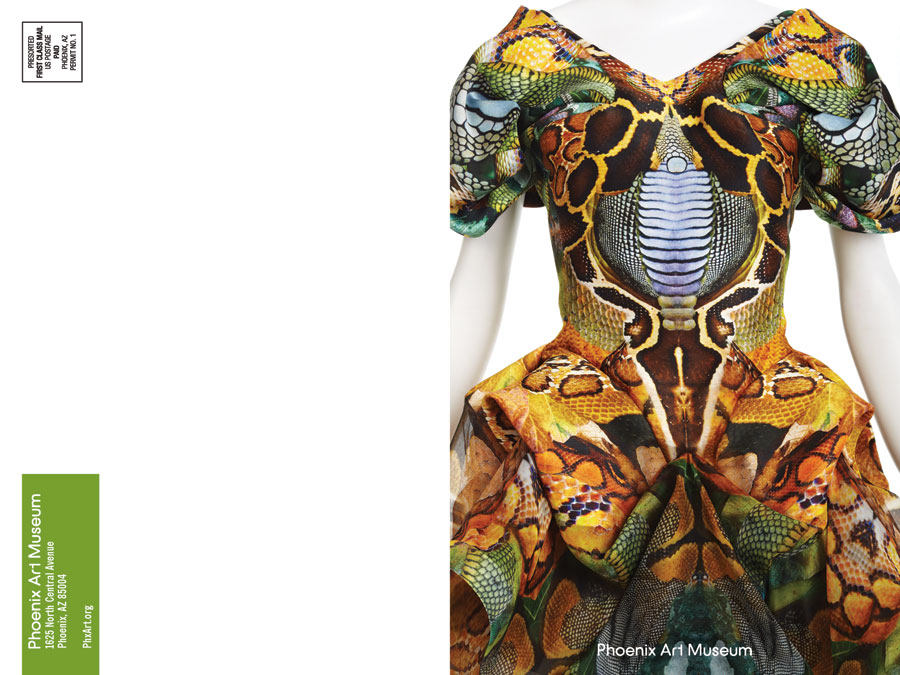

High resolution and vivid colours: Digital textile printing allows for highly detailed and vibrant prints that can match or even surpass the quality of traditional screen printing.

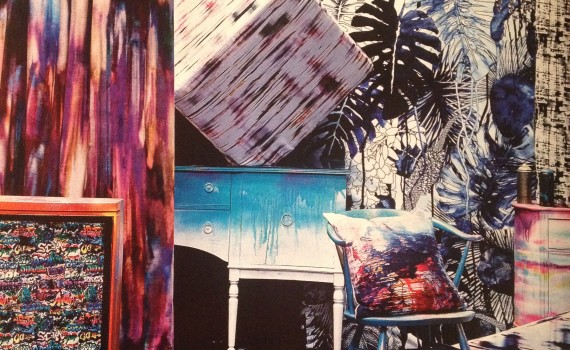

Digital printing can be used on a variety of materials in stage design, including:

Short runs and flexibility: With digital textile printing, small runs and custom designs can be easily produced without the need for expensive set-up costs associated with screen printing.

Faster turnaround times: Digital textile printing can produce prints much faster than traditional methods, allowing for quicker turnaround times on projects.

Cost-effective for small production runs: Digital textile printing is a cost-effective option for small production runs or custom designs, as it eliminates the need for expensive set-up costs.

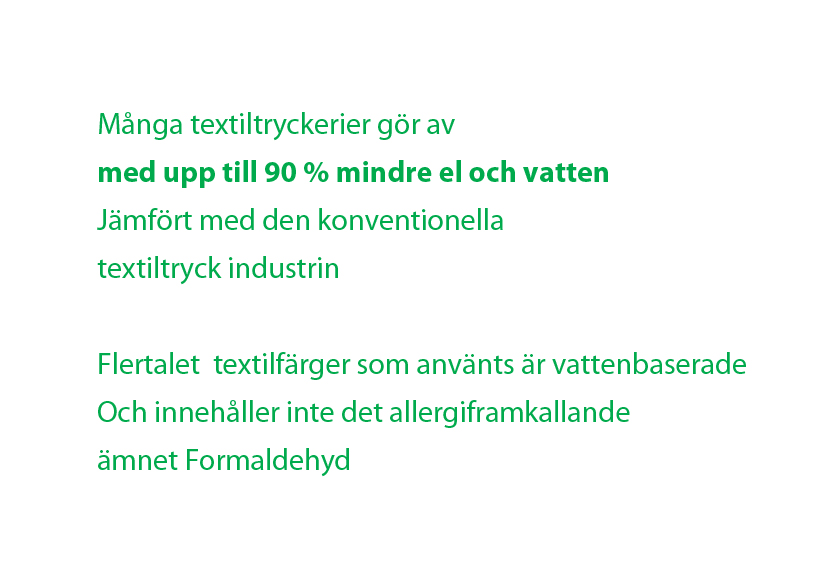

Eco-friendly: Digital textile printing uses less water and ink, which reduces the environmental impact of textile production.

Variety of substrates: Digital textile printing can be used on a wide range of fabrics, including natural fibers, synthetics, and blends.

Personalization: Digital textile printing allows for easy customization and personalization of textiles, which can be useful for small businesses and online retailers.

No color limitations: Digital textile printing allows for the use of an unlimited number of colors and color matching, which is not possible with screen printing.

Easy to use: Digital textile printing systems are easy to use and can be operated by anyone with minimal training.

Scalability: Digital textile printing allows you to start small and scale up as needed, which is perfect for small businesses and start-ups.

Sublimation Printing

Sublimation printing is one of the newest techniques in the industry. Sublimation printers use heat to transfer dye onto paper which is then transferred either on fabric or the garment itself. The method is very similar to the heat transfer method, but there is one crucial difference. The heat sublimation ink transforms from a liquid to gas before totally disintegrating into the fabric. The ink’s gaseous state allows the ink to penetrate the fabric completely instead of sitting on top of the fabric.

Best Used For:

Sublimation printing is great for all-over/seam-to-seam printing. It is also good for placement prints which would be hard to engineer on fabric by the yard. The process results in bold, vivid artwork.

Affordability:

While the quality is better, this process is much more costly than the heat transfer method because of the cost of the equipment/ink costs.

Pros:

Since the gaseous ink dissolves completely into the fabrics, the cloth remains soft to the touch.

The quality lasts longer than heat transfer or digital printing methods making it a great option for activewear and swimwear which get a lot of wear as well as exposure to sun/chlorine.

Great for designs that need detail and precision.

Cons:

Fabric options are limited- sublimation inks only work on synthetics fibers, mainly polyester or poly blends.

DTG Design and printing process

DTG printing services

Direct to Garment, or DTG printing, is a process by which a digital image is printed directly onto your apparel using cutting edge printing technology and inks. This process allows us to print any quantity order with highly detailed full color designs at an affordable price.

https://www.printful.com/custom/womens-clothing

https://www.printful.com/custom/womens/dresses/all-over-print-long-sleeve-midi-dress

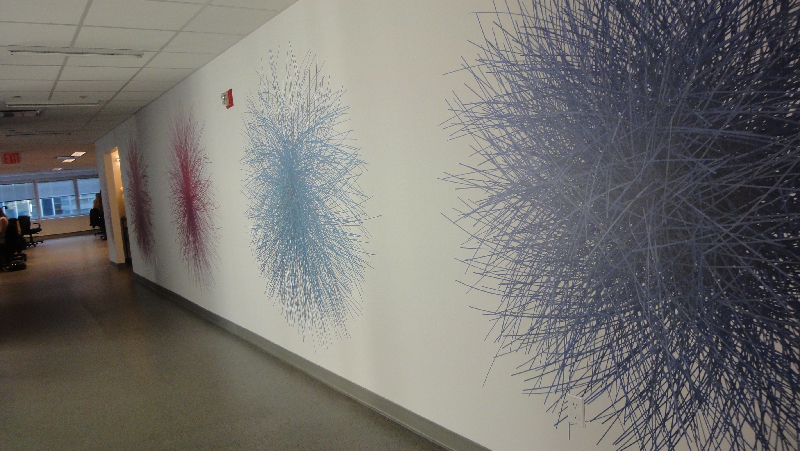

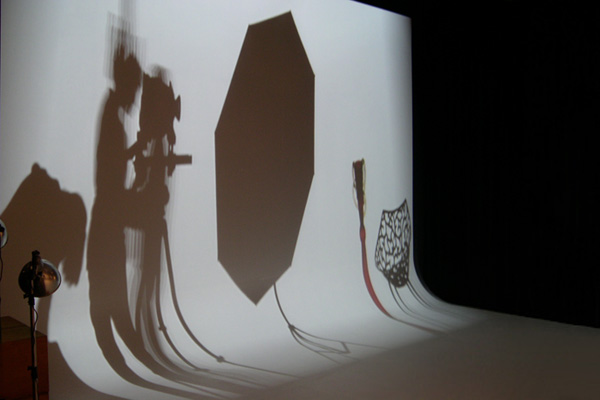

Digital printing can be used to create detailed and vibrant backdrops for stage productions. As well as:

Props: Props such as signs, banners, and posters can be easily and quickly produced using digital printing.

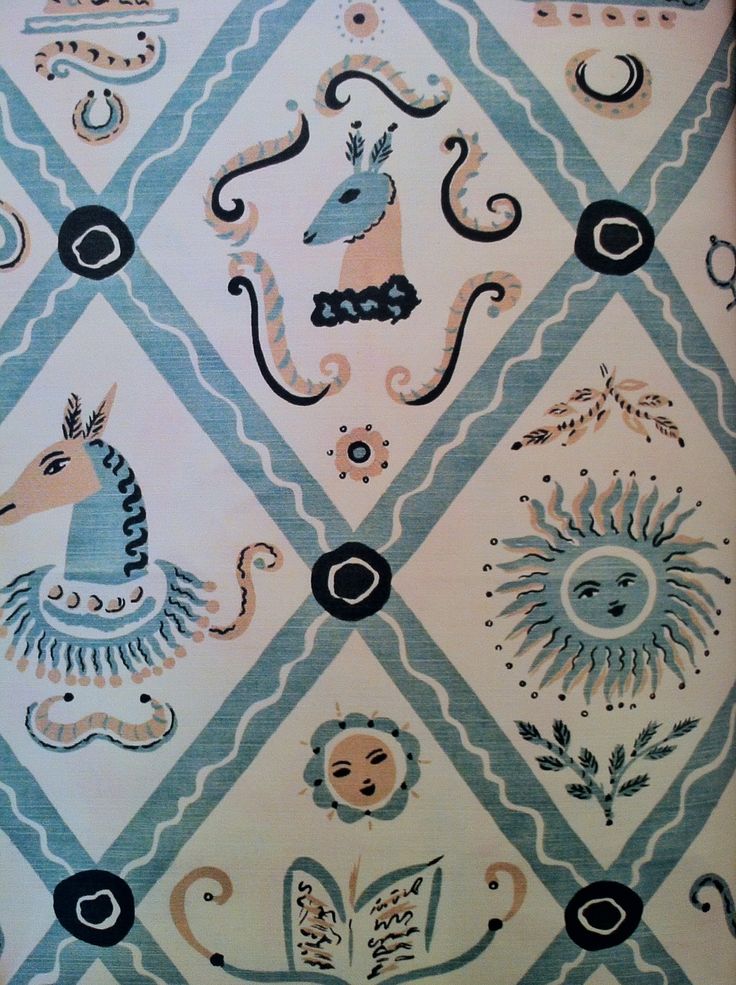

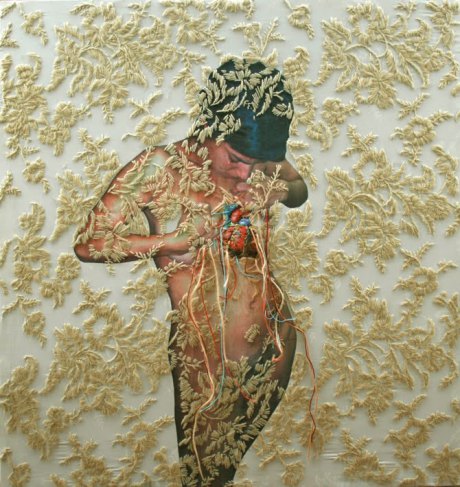

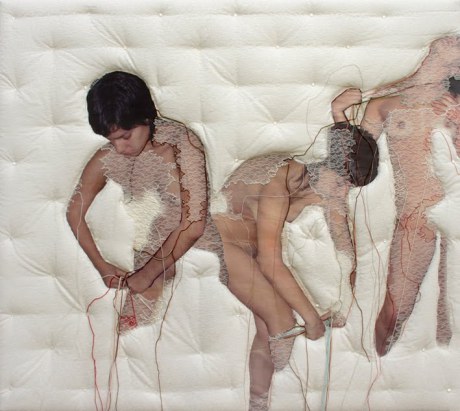

Costumes: Digital printing can be used to create detailed designs and patterns on costumes, making them more visually interesting and unique.

Set pieces: Set pieces such as furniture, walls, and floors can be decorated with digital printing, adding visual interest and depth to the set.

Flooring and carpeting: Digital printing can be used to create detailed patterns and designs on flooring and carpeting, which can be used to define different areas of the stage.

Lighting gels: Digital printing can be used to create custom patterns and designs on lighting gels, which can be used to create different lighting effects.

Scrims and projection surfaces: Digital printing can be used to create custom designs and patterns on scrims and projection surfaces, which can be used to create interesting visual effects during a performance.

Rigging and stage equipment: Digital printing can be used to create custom designs and logos on rigging and stage equipment, which can be used to add branding and visual interest to the production.

There are many materials that can be digitally printed on, including:

Printing on Glas

https://printglas.se/

Paper (such as brochures, flyers, business cards, posters, and booklets)

Cardstock

Vinyl

Fabric (such as t-shirts and banners)

Canvas

Glass

Metal

Ceramic

Wood

Plastic (such as PVC and acrylic)

Leather

Polyester

Nylon

This list is not exhaustive, as new materials are being developed for digital printing all the time. Keep in mind that not all materials can be printed on with the same type of printer,

Lets look at the ordering process at BIG IMAGE :

They say: We strive to create the biggest possible impression with the smallest possible negative footprint. Environmental considerations and social responsibility – through technological progress and business culture – are woven into every aspect of Big Image.

Colour profile

https://bigimagesystems.com/artwork/

REQUIREMENTS: it's essential to assess your requirements carefully before you order prints.

https://bigimagesystems.com/artwork/

Want to read more about technical (printers) latest developments.

https://www.texintel.com/blog/2021/2/2/sv86retxmg4m5145120qqm9btfm6jw